Staff of degreed Control Systems Engineers with 30+ years combined experience. We employ World class industry standard PLCs such as

Allen-Bradley's SLC, PLC-5, Micrologix, CompactLogix and ControlLogix.

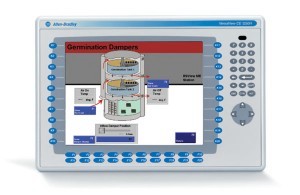

Most of our projects include operator panels, mainly PanelView, PanelView Plus, DTAM, VersaView and industrial PCs from Rockwell.

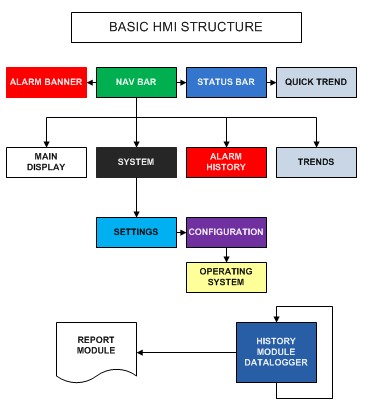

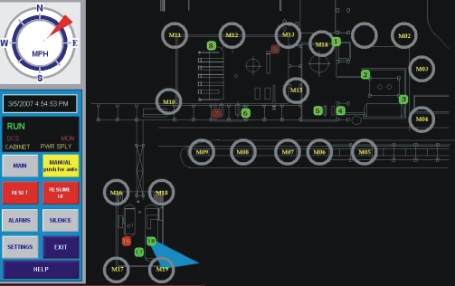

We develop PC-based

HMI (Human-Machine Interface) / SCADA (Supervisory Control and Data Acquisition) applications with the industry standard HMI software

RSView and FactoryTalk from Rockwell Automation. We deploy complete factory and plant floor automation projects, including industrial control networks (Ethernet/IP, Data Highway, DeviceNet, ControlNet, AS-i, Profibus DP, Modbus TCP and RTU), LAN, Internet, Web, wireless (900/2400 MHz ISM band), Satellite and Cellular links

ControlSystemsUSA provides wireless networking solutions with applications in SCADA, telemetry, telecommunications and online transaction markets.

We will maximize your technology investment.

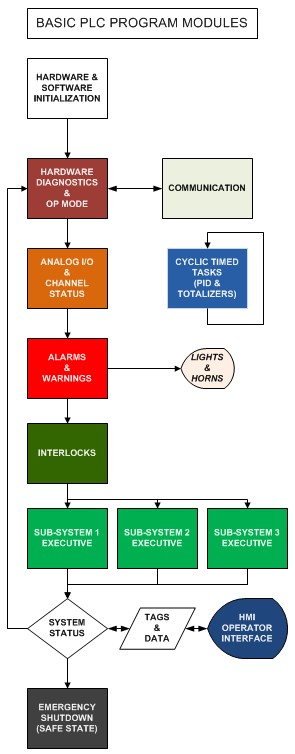

- PLC applications programming for Allen-Bradley and Siemens PLCs

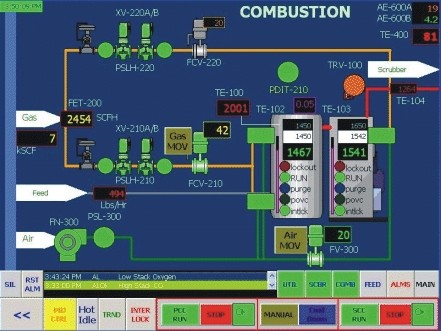

- SCADA Graphics and Database development and implementation with RSView and FactoryTalk HMI software

- AutoCAD Electronic Documentation (P&ID and Loop Drawings)

- Integration with Visual Basic .NET, Excel, Access, SQL Server and ODBC databases

- Electrical and Instrument Installation

- Process Data Collection Systems and Industrial I.T.

- Control Loop Check

- Commissioning and Startup Services

- System Training

Process Instrumentation

PanelView Plus Operator Panel

SCADA in Oil Refinery

Custom PLC-based SCADA systems for:

- Factory and Machine Automation

- Mobile SCADA and Process Control

- Oil & Gas and Pipelines

- Custody Transfer skids

- Tank Gauging

- Waste Processing

- Water Treatment

- Burners and Incinerators

- Food & Beverage

- Plastics Industry

- Conveyor Control

- Motor, Pump and Compressor Control

- Wireless Telemetry

- Data Logging

- Real-Time Process Data to Web

- Multi-Vendor Integration